1. Precautions for transporting frozen food

When transporting frozen food, special attention needs to be paid to keep the whole low temperature to prevent food deterioration. First, select the efficient thermal insulation materials, such as EPS, EPP or VIP incubator, to ensure a good heat insulation effect. Second, use a sufficient amount of technology ice or gel ice bags, evenly distributed in the incubator, to ensure a stable temperature. Avoid frequent switches and reduce air loss. In addition, exposure to high temperature should be avoided during transportation and shortened as much as possible. Temperature monitoring is also very important to take timely measures to deal with temperature fluctuations and ensure the quality and safety of food.

2. Use heat insulation and cooling packs

Of insulation and cooling packs, and when transporting frozen food. Choose high-quality insulation materials, such as EPS, EPP or VIP incubator, which can effectively isolate the external heat and maintain the internal low temperature. With technology ice or gel ice packs, these ice packs can be kept low for a long time and evenly distributed in the incubator to ensure that the food is in a low temperature environment. In addition, disposable insulation bags with aluminum foil lining can be used to further enhance the heat insulation effect. By properly matching these heat insulation and cooling packages, ensure that frozen food is not affected by temperature changes during transportation and remains fresh and safe.

3. Appropriate packaging techniques

Using appropriate packaging technology is key to ensure that frozen food maintains a low temperature during transportation. First, the food is pre-cooled to the appropriate transport temperature, and then put into a moisture-proof packaging bag to prevent the moisture influence caused by direct contact with the ice pack. Then, distribute the technology ice or gel ice bag evenly at the bottom and four sides of the incubator, and then place the food in the center to ensure that the temperature is uniform. Use aluminum foil lining or isolation film to further enhance the heat insulation effect and avoid external heat intrusion. Finally, make sure that the incubator is tightly sealed, and marked with “frozen food” on the outside, and remind the logistics personnel to handle it carefully. This maximizes the quality of the frozen food.

4. What can Huizhou do for you

When transporting frozen food, even without using dry ice, Huizhou Industrial can provide customers with a variety of packaging solutions to ensure that the food remains at the best temperature during transportation. With years of professional experience and rich product line, we provide customers with the best quality cold chain transportation solutions, to ensure that their products are not affected by temperature changes in transportation.

1.EPS incubator + technology ice

description:

EPS incubator (foam polystyrene) is a lightweight, good thermal insulation performance material. With technology ice, suitable for short distance and midway transportation, can maintain a stable low temperature environment.

merit:

-Lightweight: easy for handling and transportation.

-Good heat insulation performance: it can effectively maintain the temperature in the box.

-Low cost: suitable for large-scale use.

shortcoming:

-Poor durability: not suitable for multiple use.

-Limited scope of application: mainly suitable for short-distance and midway transportation.

2. EPP incubator + gel ice bag

description:

EPP incubator (foam polypropylene) has high strength, good durability, suitable for long-distance transportation. With a gel ice bag, it can keep it low for a long time and is not easy to melt.

merit:

-High durability: suitable for multiple use, reducing long-term costs.

-Good cooling preservation effect: the gel ice bag can keep the low temperature for a long time.

-Environmental protection: the EPP materials can be recycled.

shortcoming:

-Higher cost: higher initial purchase cost.

-Heavy weight: relatively difficult.

3. VIP incubator + technology ice

description:

The VIP incubator (vacuum insulation plate) has the top thermal insulation performance, suitable for the long-distance transportation of high-value products. With technology ice, it can ensure temperature stability and persistence.

merit:

-Excellent thermal insulation performance: can keep the low temperature for a long time.

-Applicable high value products: ensure that product quality is not affected.

-Energy saving and environmental protection: efficient thermal insulation performance reduces energy consumption.

shortcoming:

-Very high cost: transportation suitable for high value or special needs.

-Heavy weight: more difficult in handling.

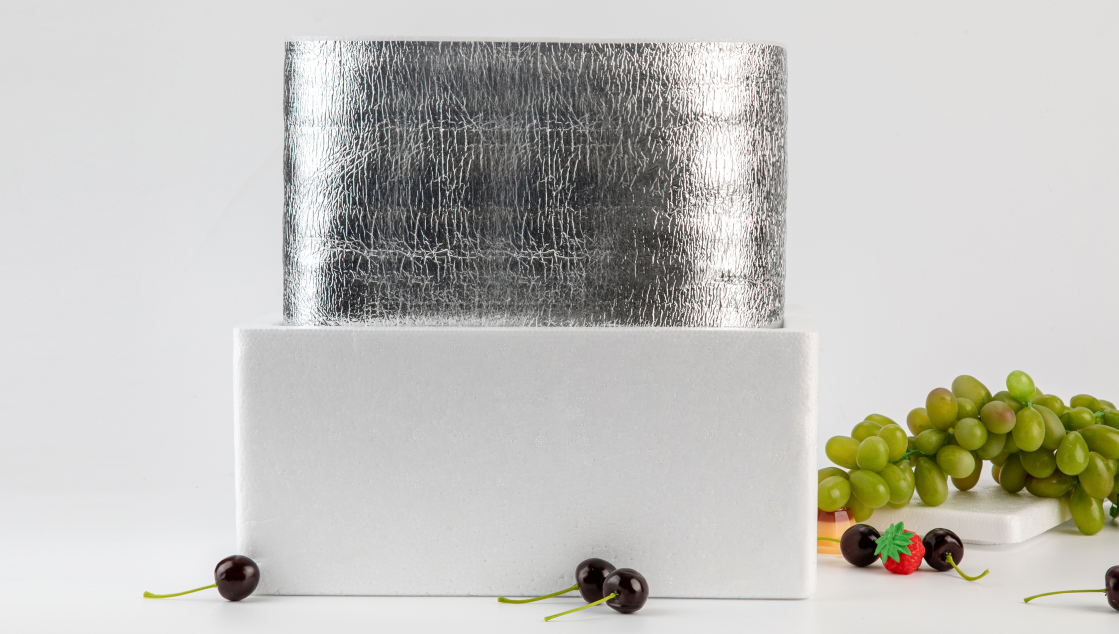

4. Disposable thermal insulation bag + gel ice bag

description:

The disposable insulation bag is lined with aluminum foil, easy to use and suitable for various types of cold chain transportation. With gel ice bags, you can maintain a moderate low temperature environment, suitable for short distance and midway transportation.

merit:

-Easy to use: no need to recycle, suitable for single use.

-Low cost: suitable for small and medium-sized transportation needs.

-Good thermal insulation effect: aluminum foil lining enhances thermal insulation performance.

shortcoming:

-Single-time use: not environmentally friendly, requiring large procurement.

-Limited cold retention time: not suitable for long-distance transportation.

5. EPP incubator + technology ice

description:

EPP incubator (foamed polypropylene) with technology ice, suitable for medium and long distance transportation, can maintain temperature stability and persistence.

merit:

-High durability: suitable for multiple use, reducing long-term costs.

-Good cold protection effect: the technology ice can effectively maintain the low temperature.

-Environmental protection: the EPP materials can be recycled.

shortcoming:

-Higher cost: higher initial purchase cost.

-Heavy weight: relatively difficult.

6. VIP incubator + gel ice bag

description:

VIP incubator (vacuum insulation plate) with gel ice bag, suitable for long-distance transportation of extremely high value products, can ensure very low temperature and lasting cooling effect.

merit:

-Excellent insulation: able to keep low for a long time.

-Applicable high value products: ensure that product quality is not affected.

-Energy saving and environmental protection: efficient thermal insulation performance reduces energy consumption.

shortcoming:

-Very high cost: transportation suitable for high value or special needs.

-Heavy weight: more difficult in handling.

With 13 years of professional experience and rich product line, Huizhou Industrial is committed to providing customers with the best quality cold chain packaging and transportation materials and services. Whether it is short or long distance transportation, whether it is ordinary frozen food or high-end frozen food, we can provide the most appropriate solution to ensure that the products are safe and stable during transportation. Choose Huizhou industry, choose to rest assured and feel at ease.

5.Temperature monitoring service

If you want to obtain the temperature information of your product during transportation in real time, Huizhou will provide you with a professional temperature monitoring service, but this will bring the corresponding cost.

6. Our commitment to sustainable development

1. Environmental-friendly materials

Our company is committed to sustainability and use environmentally friendly materials in packaging solutions:

-Recyclable insulation containers: Our EPS and EPP containers are made of recyclable materials to reduce environmental impact.

-Biodegradable refrigerant and thermal medium: We provide biodegradable gel ice bags and phase change materials, safe and environmentally friendly, to reduce waste.

2. Reusable solutions

We promote the use of reusable packaging solutions to reduce waste and reduce costs:

-Reusable insulation containers: Our EPP and VIP containers are designed for multiple use, providing long-term cost savings and environmental benefits.

-Reusable refrigerant: Our gel ice packs and phase change materials can be used multiple times, reducing the need for disposable materials.

3. Sustainable practice

We adhere to sustainable practices in our operations:

-Energy efficiency: We implement energy efficiency practices during manufacturing processes to reduce the carbon footprint.

-Reduce waste: We strive to minimize waste through efficient production processes and recycling programs.

-Green Initiative: We are actively involved in green initiatives and support environmental protection efforts.

.jpg)