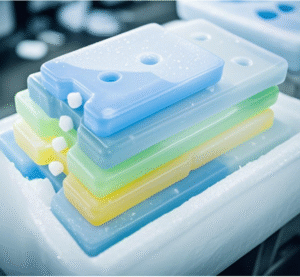

Cold Chain Ice Blocks are the silent workhorses of temperature‑controlled logistics, acting as compact thermal batteries that absorb ambient heat spikes and keep payloads within a narrow, validated range. Their cores typically employ phase‑change materials (PCMs) tuned to freeze at –20 °C, 0 ° C., atau +5 ° C.; during transit these PCMs melt slowly, holding a stable plateau that prevents vaccine hot spots and food spoilage. Modern blocks encase the PCM in puncture‑resistant HDPE or PP shells that withstand more than 100 freeze–thaw cycles, reducing waste and total cost of ownership for shippers.

Performance now hinges on three factors: latent‑heat capacity, shell conductivity, and block geometry. High‑density salt‑hydrate PCMs offer up to 300 kJ kg⁻¹ of latent energy, more than doubling the hold time of traditional water‑based gels. Sementara itu, ribbed or flat‑plate designs maximize surface area, speeding charge and discharge in fast‑moving cold rooms. To verify reliability, blocks are routinely tested under ISTA 7D and WHO/PQS protocols, ensuring variance stays below ±2 °C even in last‑mile deliveries where ambient swings exceed 40 ° C..

Sustainability is reshaping the sector. Bio‑derived PCMs from plant oils cut carbon footprints by 40 %, while RFID tags embedded in each ice block feed real‑time temperature and location data into IoT dashboards. These insights let 3PLs match block “state of charge” to actual route duration, trimming dry‑ice overuse and slashing freight weight. At end‑of‑life, recycled HDPE casings are re‑extruded into new shells, closing the materials loop and meeting Extended Producer Responsibility (EPR) mandates in the EU and California.

Tempk Ice Brick Advantage – Tempk’s Ice Brick pushes these innovations further with a food‑grade HDPE body, an optimized PCM core that delivers up to 72 hours of cold retention, and customizable sizes from 200 mL to 2 L. Its seamless surface resists punctures and wipes clean for rapid sanitization, while built‑in stacking grooves save 15 % freezer space compared with conventional blocks, giving shippers longer hold times, lower breakage, and greener lifecycle economics.