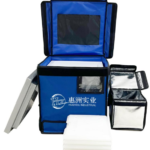

In modern cold chain logistics and daily temperature-controlled products, phase change ice has emerged as a novel thermal management tool, gaining widespread adoption due to its exceptional insulation capabilities. Our company’s 4-cells and 6-cells phase change ice products demonstrate remarkable advantages in thermal retention. This article compares these two products and analyzes their insulation performance using real-world test data.

Fundamental Principles of Phase Change Ice

Phase change ice utilizes phase change materials (PCMs) capable of absorbing and releasing heat within specific temperature ranges, thereby maintaining stable temperatures. Such technology is commonly employed in transporting temperature-sensitive goods like food and pharmaceuticals, ensuring protection against external temperature fluctuations.

Comparative Testing: 4-cells vs. 6-cells Phase Change Ice

We conducted insulation tests by placing 24-cells (traditional), 4-cells, and 6-cells phase change ice samples in foam boxes under a 35°C ambient environment, measuring their temperature maintenance time within the 0-10°C range. Test results revealed the following:

- 4-cells Phase Change Ice:

Under 35°C, the 4-cells variant significantly outperformed traditional products, extending cooling duration and delivering more stable temperature control.

Test data shows its thermal retention time reached 15.5 jam. - 6-cells Phase Change Ice:

With additional heat storage units, the 6-cells version further enhanced insulation capabilities under identical conditions.

Testing confirmed its thermal retention time extended to 21.5 jam, surpassing the 4-cells model. - Traditional 24-cells Phase Change Ice:

In the same environment, the conventional 24-cells product provided only 7 jam of thermal retention, demonstrating inferior stability and duration compared to modern designs.

Why Are 4-cells and 6-cells Phase Change Ice Preferred?

- Extended Thermal Retention: Designed for modern cold chain demands, these models ensure prolonged temperature control, safeguarding products within optimal ranges during transit.

- Enhanced Thermal Stability: Optimized cell structures and materials enable superior resistance to temperature fluctuations, maintaining consistent low-temperature conditions.

- Eco-Friendly Solutions: Made from recyclable, sustainable materials, our phase change ice reduces carbon footprints while delivering reliable thermal management.

Kesimpulan

The test data highlights the progressive improvements in thermal performance as cell numbers increase. Both 4-cells and 6-cells phase change ice products excel in delivering extended, stable temperature control for cold chain logistics and daily applications, ensuring product safety and efficacy. Moving forward, we will continue refining our designs to advance phase change ice technology, offering consumers even better temperature management experiences.