1. Notes for shipping strawberry chocolate

1. Temperature control

Strawberry chocolate is very sensitive to temperature and should be kept in the range of 12-18°C to avoid melting or qualitative change caused by too high or too low temperature. Excessive temperatures can cause the chocolate to melt, affecting the taste and appearance, and damaging the texture and flavor.

2. Humidity management

Keep a low humidity environment to prevent chocolate from moisture or dew, affecting the taste and appearance. High humidity will cause “frosting” on the surface of chocolate, a white crystal layer, which will affect the appearance of the product and consumers’ desire to buy.

3. Shock protection

Avoid violent vibration during transportation to prevent strawberry chocolate from breaking or deformation. The vibration can not only destroy the appearance of the chocolate, but may also cause the separation of the inner filling material (such as strawberries) from the chocolate, affecting the overall texture and structure.

4. Packaging safety

Use proper protective packaging to ensure that the chocolate is not squeezed and damaged during shipping. The strong packaging prevents damage to the chocolate caused by external pressure, but also provides additional insulation to help maintain the internal temperature.

2. Packaging steps

1. Prepare the materials

-Moisture-proof film or plastic wrap: used to wrap in strawberry chocolate to prevent moisture intrusion.

-High efficiency incubator (e. g., EPS, EP, or VIP incubator): used to keep internal temperature stable.

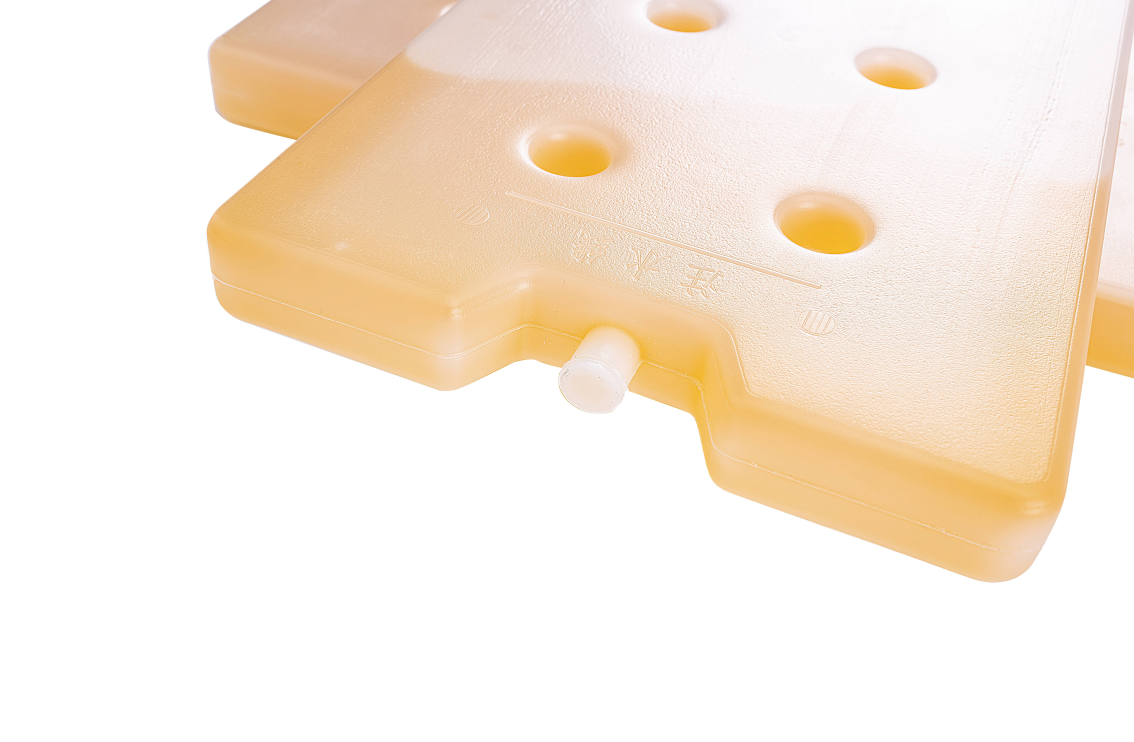

-Condensant (gel ice pack, technology ice, or water injection ice pack): used to maintain a low temperature environment.

-Foam or bubble pad: used to fill voids to prevent movement and vibration during transport.

2. Pack the chocolate pack

Wrap strawberry chocolate in moisture or plastic wrap to ensure it is protected from moisture. The moisture-proof film prevents the icing on the chocolate surface and keeps it smooth and bright.

3. Into the incubator

Place the wrapped strawberry chocolate into an incubator, and place the refrigerant at the bottom and around the box to ensure that the temperature is evenly distributed. The refrigerant can choose gel ice bag, technology ice or water injection ice bag, according to the transportation distance and time for appropriate collocation.

4. Fill in the void

Use foam or bubble pads to prevent chocolate from moving and vibrating during transport. Foam and bubble pads can provide additional cushioning to absorb the impact force in transport and protect the chocolate from damage.

5. Seal the incubator

Make sure the incubator is well sealed and labeled with “fragile items” and “refrigerated transportation” to remind logistics personnel to handle it carefully. A well-sealed incubator can effectively maintain the internal temperature and prevent cold air leakage.

3. Temperature control method

1. Choose the appropriate thermal insulation material

Using EPS, EPP or VIP incubator, these materials have good thermal insulation performance and can effectively prevent the influence of external temperature on the temperature in the incubator. EPS incubator is suitable for short-distance transportation, EPP incubator is suitable for medium and long-distance transportation, while VIP incubator is suitable for long-distance and high-value products.

2. Use the appropriate refrigerant medium

Place a sufficient amount of refrigerant (such as gel ice packs, technology ice or water ice packs) at the bottom and around the incubator to ensure a low temperature environment throughout transportation. Adjust the quantity and distribution position of refrigerant according to the transportation time and ambient temperature to achieve the best insulation effect.

3. Real-time temperature monitoring

Place the temperature monitoring equipment in the incubator to monitor the temperature change in the incubator in real time to ensure that the temperature is always maintained between 12-18°C. In case of abnormal temperature, take timely measures to adjust the position of the ice packs or increase the number of ice packs. The temperature monitoring device can be viewed in real time through a mobile phone or computer to ensure temperature transparency and security during transportation.

4. Professional solutions for Huizhou Industry

Maintaining the temperature and texture of strawberry chocolate is crucial. Strawberry chocolate needs to be transported at the right temperature to prevent melting or deterioration. Huizhou Industrial Cold Chain Technology Co., Ltée. provides a series of efficient cold chain transportation products, the following is our professional proposal.

1.Huizhou products and applicable scenarios

1.1 Inwater ice pack

-Main application temperature: 0℃

-Applicable scenario: For products that need to be kept around 0℃, such as some strawberry chocolate that needs to be kept low but does not freeze.

1.2 Saline water ice pack

-Main application temperature range: -30℃ to 0℃

-Applicable scenario: Suitable for strawberry chocolate that requires lower temperatures to ensure that it does not melt during transportation.

1.3 Gel ice pack

-Main application temperature range: 0℃ to 15℃

-Applicable scenario: For strawberry chocolate at slightly low temperatures to ensure the appropriate temperature during transportation.

1.4 Organic phase change materials

-Main application temperature range: -20℃ to 20℃

-Applicable scenario: Suitable for accurate temperature-controlled transportation in different temperature ranges, such as strawberry chocolate maintained at room temperature or refrigerated.

1.5 Ice box ice board

-Main application temperature range: -30℃ to 0℃

-Applicable scenario: Strawberry chocolate for short trips and for low temperatures.

2.insulation can

2.1VIP incubator

-Features: Use vacuum insulation plate technology to provide the best insulation effect.

-Applicable scenario: Suitable for the transportation of high-value strawberry chocolate, ensuring stability at extreme temperatures.

2.2EPS incubator

-Features: Polystyrene materials, low cost, suitable for general thermal insulation needs and short-distance transportation.

-Applicable scenario: For strawberry chocolate transportation that requires moderate insulation effect.

2.3 EPP incubator

-Features: high density foam material, provide good insulation performance and durability.

-Applicable scenario: Suitable for strawberry chocolate transportation requiring long insulation time.

2.4PU incubator

-Features: polyurethane material, excellent thermal insulation effect, suitable for long-distance transportation and high requirements of thermal insulation environment.

-Applicable scenario: suitable for long-distance and high-value strawberry chocolate transportation.

3.sac thermique

3.1 Oxford cloth insulation bag

-Features: light and durable, suitable for short-distance transportation.

-Applicable scenario: suitable for the transportation of small batch of strawberry chocolate, easy to carry.

3.2 Non-woven thermal insulation bag

-Features: environmentally friendly materials, good air permeability.

-Applicable scenario: suitable for short distance transportation for general insulation requirements.

3.3 Aluminum foil insulation bag

-Features: reflected heat, good thermal insulation effect.

-Applicable scenario: suitable for medium and short distance transportation and moisturizing strawberry chocolate.

4. Recommended plan according to the strawberry chocolate transportation requirements

4.1 Long Distance Strawberry Chocolate Shipping

-Recommended solution: Use a saline ice pack or ice box ice with a VIP incubator to ensure that the temperature remains at 0℃ to 5℃ to maintain the texture and texture of strawberry chocolate.

4.2 Short-haul strawberry for chocolate shipping

-Recommended solution: Use gel ice packs with a PU incubator or EPS incubator to maintain a temperature between 0℃ and 15℃ to prevent strawberry chocolate from melting during transportation.

4.3 Midway strawberry for chocolate shipping

-Recommended solution: Use organic phase change materials with an EPP incubator to ensure that the temperature is maintained within the appropriate range and maintain the freshness and quality of strawberry chocolate.

By using Huizhou’s cold storage and insulation products, you can ensure that strawberry chocolate maintains the best temperature and quality during transportation. We are committed to providing our customers with the most professional and efficient cold chain transportation solutions to meet the transportation needs of different types of strawberry chocolate.

5. Temperature monitoring service

If you want to obtain the temperature information of your product during transportation in real time, Huizhou will provide you with a professional temperature monitoring service, but this will bring the corresponding cost.

6. Our commitment to sustainable development

1. Environmental-friendly materials

Our company is committed to sustainability and use environmentally friendly materials in packaging solutions:

-Recyclable insulation containers: Our EPS and EPP containers are made of recyclable materials to reduce environmental impact.

-Biodegradable refrigerant and thermal medium: We provide biodegradable gel ice bags and phase change materials, safe and environmentally friendly, to reduce waste.

2. Reusable solutions

We promote the use of reusable packaging solutions to reduce waste and reduce costs:

-Reusable insulation containers: Our EPP and VIP containers are designed for multiple use, providing long-term cost savings and environmental benefits.

-Reusable refrigerant: Our gel ice packs and phase change materials can be used multiple times, reducing the need for disposable materials.

3. Sustainable practice

We adhere to sustainable practices in our operations:

-Energy efficiency: We implement energy efficiency practices during manufacturing processes to reduce the carbon footprint.

-Reduce waste: We strive to minimize waste through efficient production processes and recycling programs.

-Green Initiative: We are actively involved in green initiatives and support environmental protection efforts.

.jpg)