In industries ranging from food delivery to pharmaceuticals, maintaining the integrity of temperature-sensitive goods during storage and transit is a top priority. Insulated boxes have become a cornerstone of modern logistics, offering robust protection against environmental fluctuations while ensuring compliance with safety standards. Whether shipping fresh produce, vaccins, or gourmet meals, these containers are engineered to preserve quality, réduire les déchets, and meet stringent regulatory demands.

The Critical Role of Insulated Boxes

Temperature deviations during shipping can lead to spoilage, pertes financières, and reputational damage. Insulated boxes act as a shield, creating a stable microenvironment that:

- Extends Shelf Life: Slows heat transfer to keep contents within safe ranges (Par exemple, frozen, chilled, or ambient).

- Reduces Risk: Prevents bacterial growth in food or degradation of pharmaceuticals.

- Supports Sustainability: Reusable designs minimize single-use packaging waste.

Key Features of High-Performance Insulated Boxes

1. Advanced Insulation Technology

Premium boxes use materials like expanded polystyrene (PSE), polyurethane foam, or vacuum-insulated panels (VIPs) to achieve superior thermal resistance. These layers block external heat or cold, maintaining internal temperatures for 24–72 hours depending on design.

2. Durable and Weatherproof Construction

Heavy-duty exteriors made of corrugated plastic, aluminum, or reinforced cardboard resist moisture, punctures, and UV exposure. Sealed seams and airtight closures enhance protection in harsh conditions.

3. Customizable Configurations

Adjustable compartments, gel pack slots, and phase-change materials (PCMS) allow businesses to tailor insulation strategies for specific products, such as frozen meals or lab samples.

4. Regulatory Compliance

FDA-approved materials and designs ensure safe transport of food and pharmaceuticals, meeting global standards like HACCP or GDP (Good Distribution Practices).

5. Cost-Effective Reusability

Sturdy builds enable multiple uses, lowering long-term costs and environmental impact compared to disposable alternatives.

Industries Leveraging Insulated Boxes

- Food & Beverage: Meal kits, laitier, fruit de mer, and fresh produce.

- Healthcare: Vaccins, insuline, biologics, and clinical trial samples.

- E-Commerce: Subscription boxes, chocolates, and specialty goods.

- Agriculture: Flowers, plants, and live cultures.

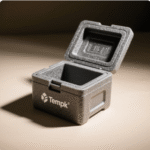

Tempk Thermal Bags: Perfect Partners for Insulated Boxes

While insulated boxes excel in bulk or long-haul transport, Tempk’s thermal bags offer agile, last-mile solutions for smaller shipments or final delivery stages. Designed to complement insulated boxes, Tempk’s products enhance cold chain efficiency with:

Why Choose Tempk Thermal Bags?

- Superior Insulation: Multi-layer foam and reflective liners retain temperatures for 6–12 hours.

- Léger & Portable: Ergonomic handles and compact designs simplify handling for couriers.

- Leakproof & Hygienic: Waterproof interiors contain spills and resist odors, with easy-wipe surfaces.

- Brand Customization: Add logos or colors to reinforce brand identity during deliveries.

- Eco-Friendly Design: Réutilisable, recyclable materials align with sustainability goals.

Conclusion

Insulated boxes are indispensable for safeguarding perishables across industries, but their effectiveness is amplified when paired with Tempk’s thermal bags. Together, they create a seamless cold chain solution—from warehouse to doorstep. Tempk’s commitment to innovation, durability, and eco-conscious design ensures your goods arrive fresh, compliant, and ready to impress.