We can support a variety of different SHAPES, MATERIALS and TEMPERATURE CONTROL DURATION Ice Bricks

according to the needs of YOUR specific products.

Free to customize size, color and printing

Supported temperature ranges

-70℃ | -25~-15℃ | 0~5℃ | 2~8℃ | 15~25℃

Block size and thickness as well as internal PCM temperature can be customized to suit

Durable, thick bricks that are beautifully shaped, often ice bricks can hold more content and make the cold last longer

The ice bricks are made of phase change material (PCM) as internal refrigerant and outer HDPE box. It has been carefully designed for better temperature control and higher quality

Ice bricks can be re-frozen, recovered and recycled to reduce costs

Mainly includes water injection and self-absorption, particularly cheap and easy to use

Also known as HDPE ice packs or PCM ice packs, they are more durable and can be used more often, and the phase change temperature can be customized.

Containing both disposable and durable types, it ensures that pharmaceuticals or biologics are delivered safely and intact to their destinations during cold chain transportation.

With the lightweight characteristics of EPS foam box but more durable, can be customized in various colors and styles

Sturdy and beautiful, especially great at picnics

For lunch, delivery and takeaway use, in a variety of shapes, sizes and materials

Containing high quality pearl cotton aluminum-plated film, suitable for cold chain transportation of a variety of products

Disposable, lightweight, inexpensive, can be used with a variety of ice packs and ice boxes

Cold chain packaging plays an important role in food transportation. It utilizes heat preservation boxes, ice pads, etc., to create a constant low-temperature environment for food, prolong the freshness period and inhibit the growth of bacteria. Whether it is fresh fruit, meat or dairy products, cold chain packaging can maximize the freshness and safety of food to meet consumer demand for quality food.

During the transportation and storage of medicines, it is crucial to maintain a suitable temperature environment. Cold chain packaging not only avoids the reduction or inactivation of drug efficacy due to temperature fluctuations, but also prevents bacterial growth and ensures the sterility and safety of medicines. Whether it is biological products or traditional medicines, cold chain packaging plays an indispensable role in pharmaceutical logistics.

During the transportation of flowers, the use of cold chain packaging can effectively extend the freshness of flowers. Providing a constant low temperature environment for the flowers, thus maximizing their freshness and beauty. Cold chain packaging is ideal for ensuring the quality of your flowers, whether they are delivered locally or shipped over long distances.

For some cosmetics with a short shelf life, the use of cold chain packaging can significantly extend their expiration date. Cold chain packaging utilizes ice pads or refrigerants to create a constant temperature and low temperature storage environment for cosmetics. Whether it's lotions, essences or other active ingredients, cold chain packaging is a powerful way to protect product quality and extend shelf life.

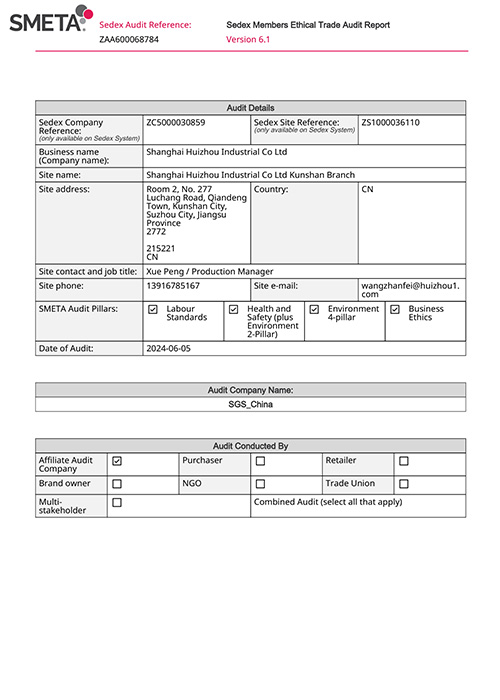

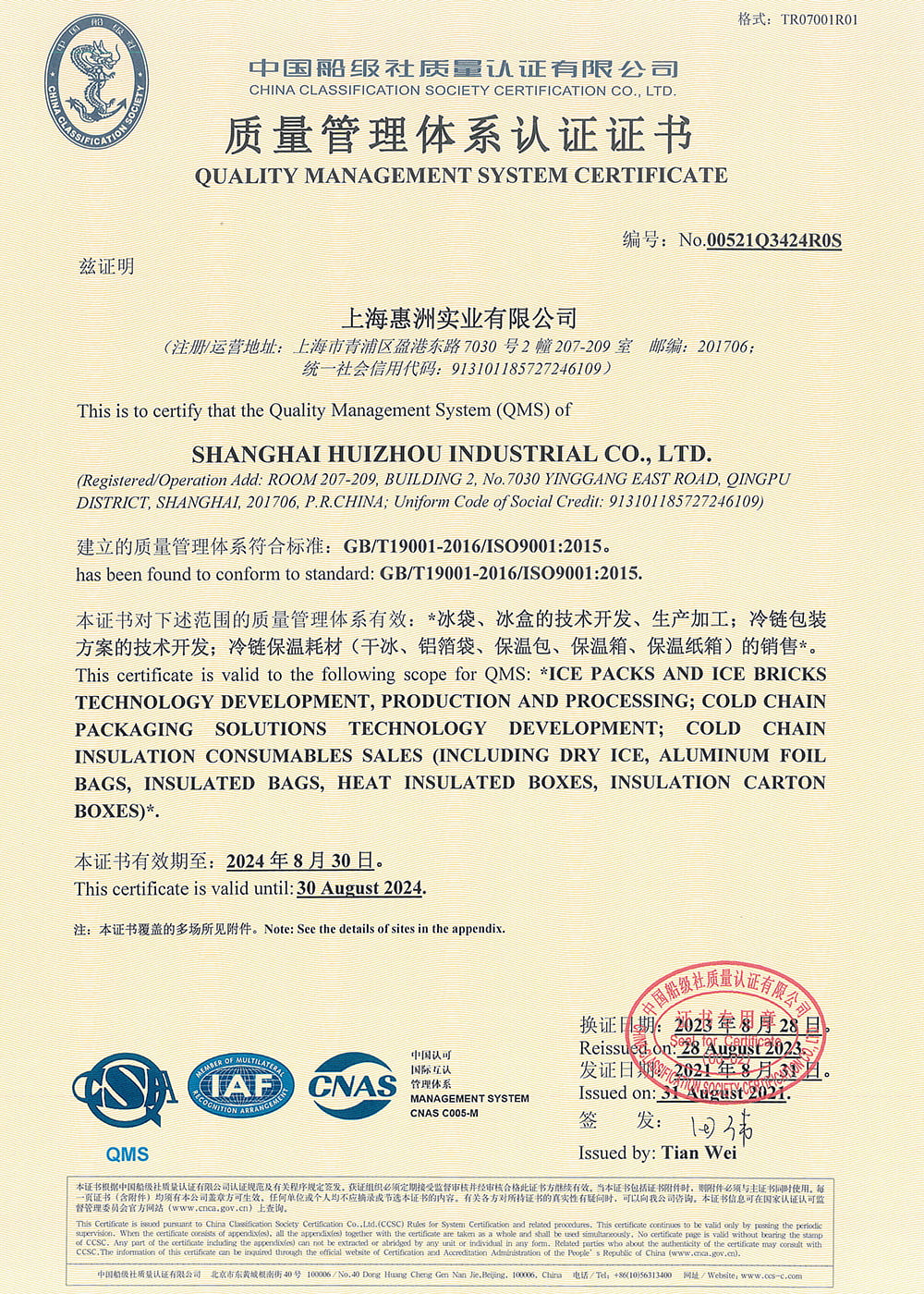

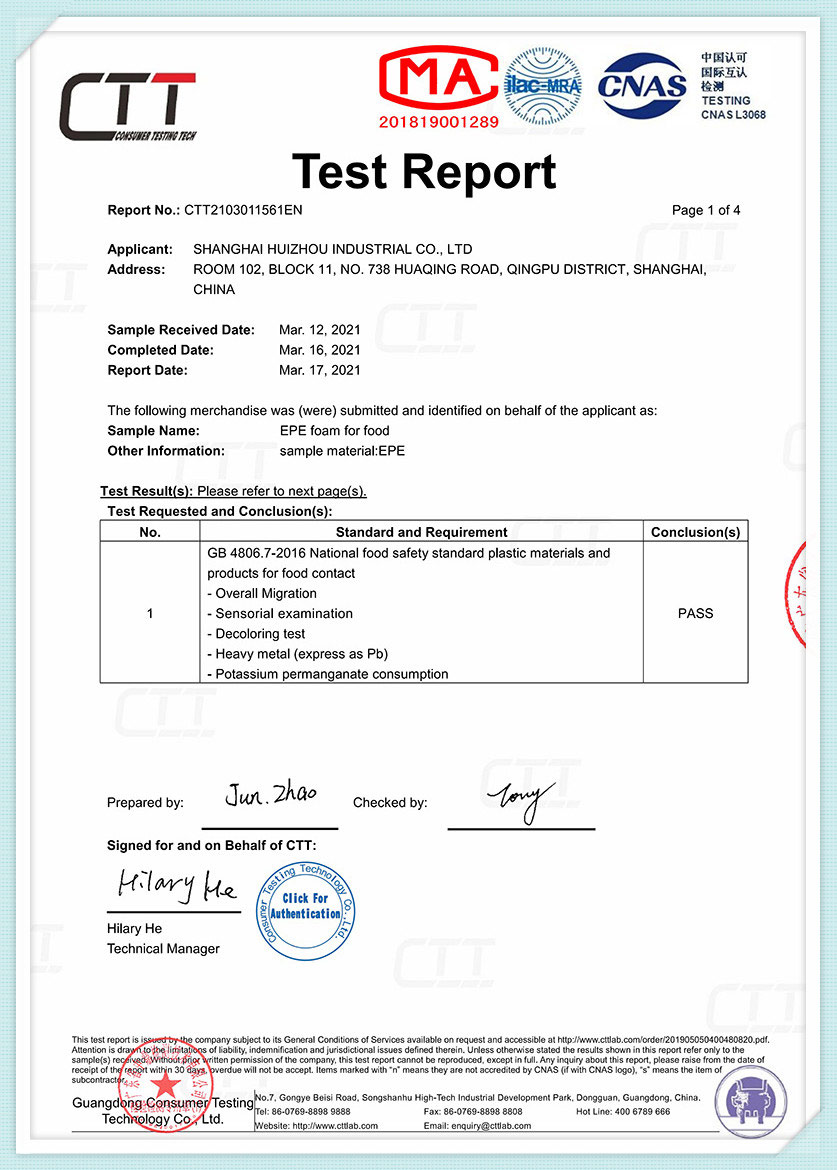

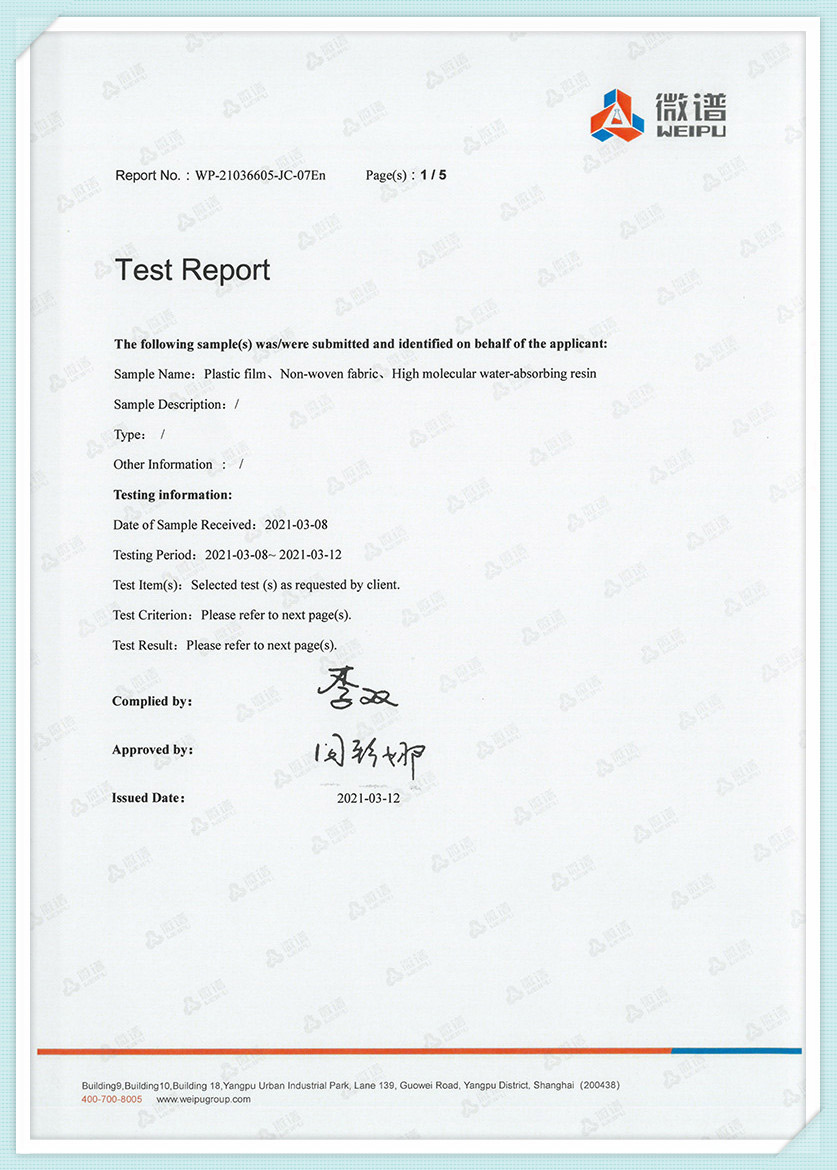

Excellent R&D team and ISO/IEC17025:2017 and CNAS certified lab

Perfect equipment to ensure production efficiency

.png)

Skilled laborers and dedication to excellence

Tidy work area and standardized work flow

Sufficient production capacity to guarantee large-volume requirements

Multi-channel logistics to ensure that the goods are transported as scheduled

Tempk, a brand of Shanghai Huizhou Industrial Co., Ltd. We focus on providing temperature control products to individuals and businesses to meet the personalized temperature control application scenarios of family and businesses.Our extensive product range includes Outdoor Insulated, Insulin Temp Carriers, Personal Thermotherapy Devices,Home & Kitchen Appliances and Temperature-Controlled Packaging.

State-of-the-Art R&D and Manufacturing Located in Shanghai, our 1,400m² R&D center operates in strict compliance with CNAS and ISTA standards. Equipped with advanced experimental equipment, our R&D team continuously innovates to enhance product quality and performance. We have established ISO-certified factories in many cities across China, ensuring timely delivery even during peak periods. With over 30 technical patents, we are at the forefront of advancing temperature-controlled packaging technology.

The Burrfield viscometer is a device used to measure the viscosity of fluids. It consists of a rotating spindle immersed in the fluid, and the resistance to the rotation of the spindle is used to determine the viscosity of the fluid. The viscometer is commonly used in industries such as food processing, pharmaceuticals, and petrochemicals to ensure the quality and consistency of fluids.

The DSC is an analytical instrument used to measure the heat flow into or out of a sample as a function of temperature or time. It is commonly used to study the thermal properties of materials, including phase transitions, melting points, glass transitions, crystallization, and chemical reactions.

A heat flow meter is a device used to measure the rate of heat transfer through a material or system. It typically consists of temperature sensors and heat flux sensors that can accurately measure the amount of heat passing through a surface or material.

1-scaled.jpg)